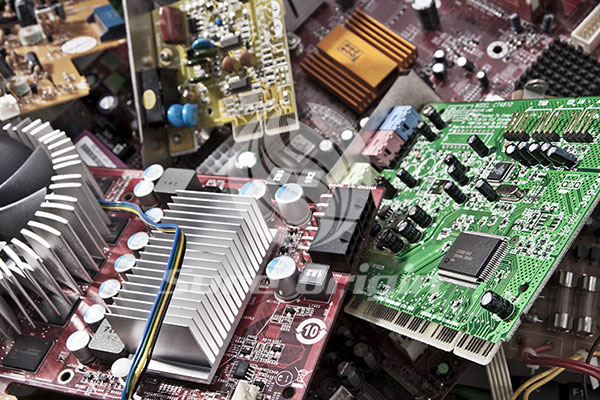

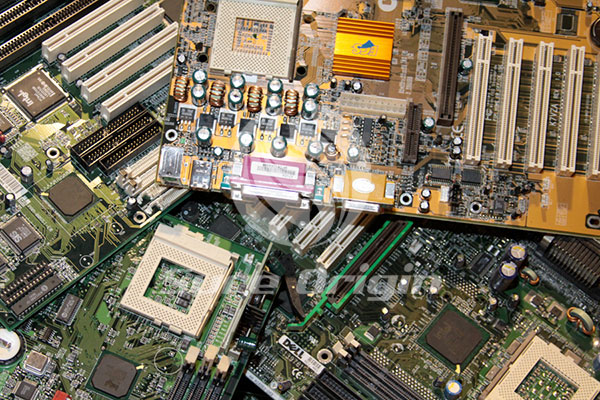

PCB circuit board dismantling machine is used to dismantle the electronic components from all kinds of printed circuit boards, such as computer boards, cell phone boards, TV boards, etc.

Capacity: 300-500kg/h

Application: PCB circuit board recycling

PCB dismantling machine is used to dismantle circuit boards into two parts:mother boards and electronic components. Electronic circuit board and other electronic components contain a large number of precious metal. By using this machine, all the ferrous metals and precious metals can be separated effectively and cleanly, and high value metals such as copper, aluminum, tin, gold, silver and platinum can be obtained.

PCB dismantling machine can be powered by nature gas or electricity. The roller part can be heated up to 400 degree. The tin on circuit board will be melted, and the electronic components(card slots, capacitors, chips, etc.) will be dropped from the circuit board with the running of the main engine. You can also use a vibrating screen to further sort the components.

The inner tank of the circuit board high temperature dismantling machine uses the 6mm-thick No. 45 anti-skid steel plate, and the outer wall is insulated with the insulating cotton to prevent the loss of temperature and the corresponding production technology; safe and reliable, stable performance, durable and other characteristics, use the automatic heating device of automatic temperature control, forced air supply and flame-out self-ignition control, and set up the automatic memory preservation of temperature per time.

Harmful gas released from cavity can go into the 3-grade air cleaning system. This machine is including 3-grade air cleaning system to clean air via activated carbon adsorption, dust collection and water spraying adsorption, which is environment-friendly. It is easy to operate, save labor and not harmful for workers.

| Model | Temperature (℃) | Speed (r/min) | Power (kw) | Dimension (mm) | Weight (kg) |

| SY-C-80-90 | 25-300 | 5-60 | 3.75 | 1680*980*1420 | 585 |

| SY-C-90-110 | 25-300 | 5-60 | 4.75 | 1880*1080*1580 | 870 |

Please leave your contact information and requirements, so that our professional team can contact you ASAP.